Oil has been gushing into the Gulf of Mexico for almost 90 days because, in part, the well’s blowout preventer didn’t work. And as it turns out, the blowout preventers on the relief wells — the relief wells that are the only way to permanently stop the oil from leaking — were also found to have “performance problems.”

Interior Secretary Ken Salazar noted this week that the relief wells’ blowout preventers, or BOPs, had been recently checked out under new testing requirements and found to have problems themselves, which have since been repaired.

As ProPublica pointed out today, Salazar mentioned the problems in a memo on the new deepwater drilling moratorium, sent this week to the new director of the drilling regulatory agency:

It is clear that the apparent performance problem with the Deepwater Horizon’s BOP is not an isolated incident. Performance problems have also been identified in recent weeks with the BOPs on the relief wells that BP is drilling. The problems have been uncovered during new testing requirements that were imposed on the relief wells after the BP Oil Spill, thus providing more evidence that prior testing requirements were inadequate. It is unlikely that these problems are unique to BP. The BOPs are manufactured by a very small number of companies, and BOPs used across the industry tend to employ standardized components.

The Interior Department says the problems with the relief wells’ BOPs have been repaired.

In the memo, Salazar is arguing that drilling on rigs with the same kind of BOPs should be stopped until Nov. 30. One of his biggest reasons is that all BOPs, because they’re made by a handful of companies to industry standards, could be facing the same problems that caused the current catastrophic leak.

But when the 29 other deepwater rigs were inspected between April 27 and May 4, only one was issued a citation relating to its blowout preventer. That rig — which is now operating one of the relief wells — was cited for not alternating between control stations while testing the BOP.

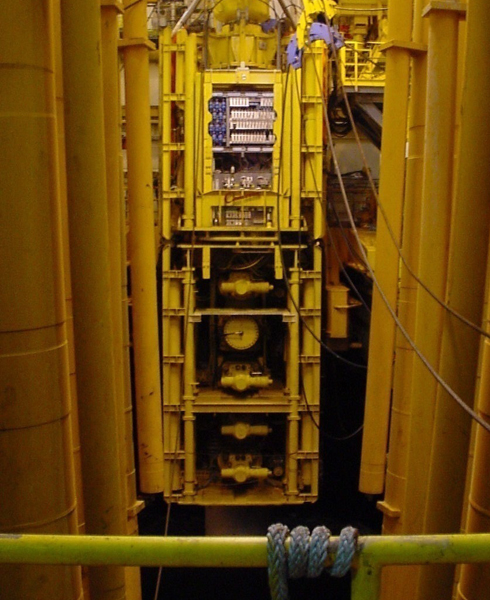

If you’re interested, here are some of the specific problems that were found with the relief well BOPs, via the Interior Dept:

- During ROV hot stab testing, the Lower Marine Riser Package disconnect function was unsuccessful because of a leaking shuttle valve.

- A failed shuttle valve caused an unsuccessful test of the All Stabs Retract function.

- A failure of the deadman test because a shuttle valve was installed that should not have been.

- A broken solenoid connection on the blue pod that prevented that pod from closing the casing shear rams.