TINY CASEY

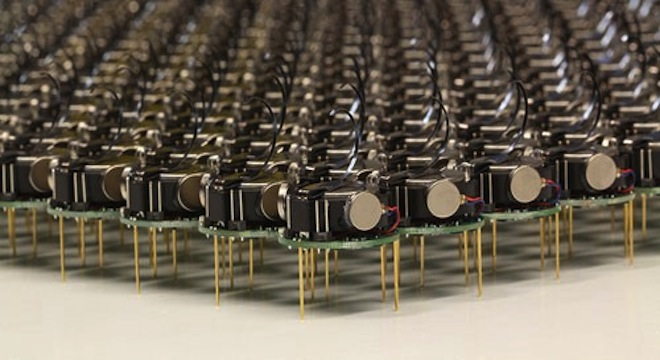

If you’ve ever wanted to control your own swarm of tiny robots, you’re in luck: Harvard is partnering with a Swiss robotics manufacturer to bring its quarter sized, collective behavior robots, called “Kilobots,” to market.

Though the name sounds ominous, it refers to the robot’s potential for mass production and coordination. Kilobots cost only about $14 apiece and can be assembled in just a few minutes.

That’s quite a contrast with conventional miniature robots, which can cost hundreds or more for just for the mechanism required to make them move independently of human operation.

And now, they’ll be manufactured and made available to everyone thanks to K-Team Corporation, a Swiss robotics manufacturer that has signed a deal with the robot’s inventors at Harvard’s Wyss Institute for Biologically Inspired Engineering, Harvard announced on Monday.

Kilobots share the basic characteristics desirable in a collective-behavior robot, including on-board computers and the ability to sense and communicate with their fellow robots. The collective behavior is inspired by social animals, including ants and bees, according to Harvard.

These features enable Kilobots to perform the most common tasks assigned to robot swarms, such as the ability to find an object and deliver it to a home base. The operation is more complicated than it may seem because, in addition to avoiding collisions with each other, some robots in the swarm must decide to give up the hunt and assume the role of a beacon to guide the others home.

The main key to the kilobot’s low cost is that it operates on an entirely different principle of mobility than typical swarming robots. Rather than using wheels, it carries two tiny vibrating motors. The vibrations travel down stick-thin legs and enable the robot to move in any direction.

If that sounds like the old children’s table-top toy in which teams of tiny plastic football players propelled themselves across a vibrating metal football field, the foundational principle is similar. It is based on slip-stick dynamics, in which movement is generated by a rapid series of displacement and friction. The Kilobot’s two motors alternate and coordinate to make the robot turn on its vertical axis as well as to move forward.

In order to reduce human intervention to a bare minimum, the research team, lead by Radhika Nagpal of Harvard’s Wyss Institute, designed Kilobots to be programmed collectively, all at the same time, by an overhead infrared transmitter. The transmitter eliminates the need to plug a cable into the robots by hand.

Kilobots also power up and down remotely and recharge themselves (they run on lithium-ion batteries) as needed.

The hitch, of course, is that Kilobots need a smooth, flat surface on which to function, but then again their primary purpose is to test commands for swarms of other robots, regardless of their operating environment.

Such swarms are already on the horizon, one example being a collective of ocean-exploring robots under development at the University of California-Davis through a National Science Foundation grant. NASA has also been working on a robotic swarm concept leading to the development of miniature robots that link with others to create larger devices that can reassemble themselves to match environmental conditions, perform tasks and even repair themselves.

With the steady increase in the use of military drones, it should be no surprise that the U.S. Army is in the game, with the development of more sophisticated platforms enabling soldiers to interact effectively with robot swarms.