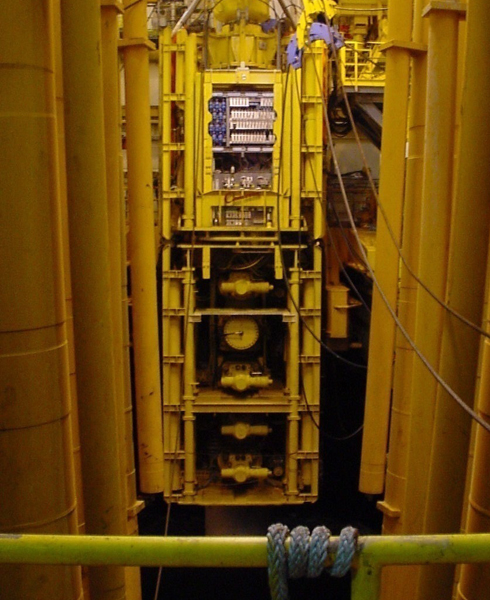

The Deepwater Horizon’s blowout preventer, the massive structure meant to stop the well from blowing out and spilling millions of barrels of oil, failed in part because BP and its contractors weren’t keeping up with its maintenance, BP’s own investigation into the disaster found.

In a report released today, BP’s investigators wrote that the blowout preventer had problems when the well blew on April 20 — problems that could have been detected.

“There were conditions in the BOP [blowout preventer] system could have impaired its performance prior to and after the accident,” the report reads. “The investigation team concluded that most of these conditions (e.g., hydraulic system leaks, solenoid valve coil faults) should have been detected by the BOP diagnostic capability that was available to the rig crew and subsea personnel by the routine BOP testing and maintenance program.”

That, like much of the report, is a shot at Transocean, the company which operated BP’s rig. The rig crew was made up of Transocean employees. The report notes that maintenance records were not accurately reported.

The blowout preventer was the last of eight prevention methods that failed, which you can see on this BP graphic:

But even the routine testing schedule, if followed, may not have been sufficient.

“Through a review of rig audit findings and maintenance records, the investigation team found indications of potential weaknesses in the testing regime and maintenance management system for the BOP,” the report reads. For example, the diagnostics system would not have found problems with critical components, like batteries.

The report notes that there were six ways the blowout preventer could have closed the wellhead. All failed. Of those, two of the methods failed because of the “condition of critical components,” according to the report.

Problems included the use of a non-manufacturer part, six leaks in the hydraulic system and modifications BP says it wasn’t aware of.

It also brings up an issue with the design of blowout preventers themselves. Of the different ways a blowout preventer can shut down a well, according to the report, they all rely on the same basic operations. So one failure can render the blowout preventer useless.

The investigation isn’t comprehensive, the report notes, since investigators didn’t have access to the blowout preventer and the manufacturer, Cameron International, didn’t supply a similar model for the investigation. But the blowout preventer is now being transported to shore, where it is expected to be examined by federal investigators.