Imagine that every time Detroit wanted to build a new car, they’d skip the step of a blueprint.

Instead, they’d task each of their departments–the steering wheel engineers, the body designers, the tire makers–to make random changes. Then they’d combine all those new products in thousands of random ways, and see which resulting car crashed the least.

It sounds crazy, but that’s what synthetic biologists have historically done when they want to design a new living cell. They’d make random changes and see which cell does the desired job the best.

Now, a computer program has added some order to the process. It doesn’t quite create a blueprint for a cell, but it lets synthetic biologists predict ahead of time how a cellular product will be made.

Living cells are mini-factories, teeming with production, packaging, and shipping activities. For synthetic biologists, a cell is a factory that can be taken over and reorganized. They can coax a cell to produce more or less of any protein, or give it instructions to make something entirely new–perhaps a protein that lights up the cell, a drug to treat a human disease, or a chemical useful to an industry.

The new computer program has its roots in one scientist’s frustration with the old trial-and-error process involved in this.

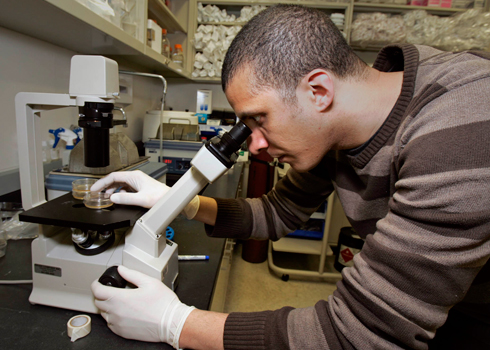

As a postdoc, Howard Salis was trying to move a genetic program from a photosynthetic bacteria to Escherichia coli, a bacteria that’s notoriously easy to manipulate in the lab.

The idea: make an E. coli strain that can convert light to energy. Salis had to program seven separate steps into the E. coli for it to do this. This meant adding seven genes to the bacteria. Each gene would be used as instructions to make a protein. The seven resulting proteins acted together to sense light and use it to produce cellular energy.

But Salis kept getting stuck. When they added new genes to a cell, scientists couldn’t predict how much of the corresponding protein would be made. So if the end result wasn’t working–in this case, photosynthesis–they wouldn’t know which of the seven steps was creating a bottle neck. To try to work through this, scientists like Salis would make random changes to all the genes and see which produced the best outcome.

“It was really frustrating,” says Salis. “And I knew that I wasn’t the only one frustrated with this trial-and-error method.”

So Salis–now a synthetic biologist at Penn State University–decided to tackle the problem head-on. He started writing a computer program that could analyze a DNA sequence and determine how much corresponding protein a cell would make.

“It all comes down to this super giant protein-making machine called the ribosome,” says Salis.

Genes are read by a cell and used to make a strand of genetic material called RNA. When a ribosome binds to an RNA strand, it produces the corresponding protein. How much protein is made depends on how tightly–and for how long–the ribosome binds to the RNA.

Salis developed a software program that calculates the strength of binding between a ribosome and any RNA strand. This is used to determine the rate of protein production.

In addition, he developed a feature of the program that can tell a scientist how to change their gene sequence to make more or less of the protein.

“If you would like to make ten times more of a protein,” he explains, “then you can put in your existing gene sequence and tell the program to optimize it for ten times more production.

The computer goes through all the possible mutations and gives you the best one.” The software is explained in the latest issue of Methods in Enzymology.

Now, Salis is using the program to tackle a new problem: how to generate energy from the parts of corn or sugar cane that humans don’t eat. He’s trying to make bacteria that can turn these plants into gasoline.

Other labs are using Salis’s software in other ways. The company Genomatica turns living cells into production centers for industrial chemicals, such as a chemical used in spandex and running shoes. They’re using the software to optimize these processes.

In a car factory, you don’t want to make steering wheels twice as fast as you make windshields–you’ll end up with too many steering wheels and not enough windshields.

Likewise, if you want cells to produce compounds, whether they’re drugs, industrial chemicals, or energy, you need each part made in the right proportion. Salis has made that easier.

Sarah C.P. Williams is a freelance science writer based in Kailua, HI.

Have a story idea or tip for Idea Lab? Please send them to idealab@talkingpointsmemo.com.