TINA CASEY

Scientists at the University of Illinois are developing a self-healing electronic circuit that could mean a far longer lifespan for next-generation cell phones and other electronic devices, as well as for batteries. Aside from saving money for consumers, the new “autonomous” circuit could help untangle the complex chain of environmental issues that wraps around broken electronic products and spent batteries.

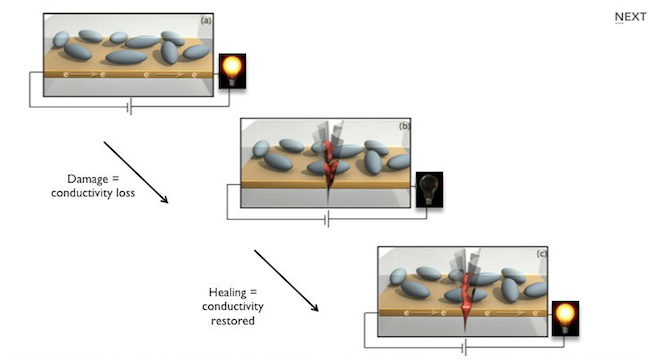

The basic concept of a self-healing circuit is fairly straightforward. The U of I team developed tiny capsules about ten microns (ten millionths of a meter) in diameter that are filled with a liquid metal and inserted alongside the circuit. When the circuit breaks, so do the capsules. The liquid metal seeps into the crack and restores the circuit.

As explained by U of I chemistry professor Jeffrey Moore in a recent press release:

“It simplifies the system. Rather than having to build in redundancies or to build in a sensory diagnostics system, this material is designed to take care of the problem itself.”

Self-healing circuits could help solve a sustainability conundrum for the rapidly growing consumer electronics market: batteries are essentially non-repairable, and many products are far cheaper to replace than to pay someone for repair work.

For that matter, as electronic technology keeps pace with Moore’s Law, electronic chips are becoming smaller, more densely packed and more complex, leaving fewer opportunities for human hands to fix a problem. The result is a rapidly growing mountain of e-waste.

Aside from helping to deal with consumer e-waste issues, autonomous circuits could become a significant factor in advanced applications, particularly aeronautics and military equipment, where there is little or no time for a lengthy diagnostic process let alone manual repairs.

U of I’s self-healing system works almost literally on the fly, with the potential to effect repairs before a human operator is aware that the circuit was even broken. In lab tests using just a small number of microcapsules, the U of I self-healing system repaired broken circuits in fractions of a second, and the research team reported that 90 percent of their samples were restored to within one percent of their full conductivity.

Autonomous materials research is a developing field that began with applications involving bridges and other structures.

Researchers in the Netherlands, for example, are developing a strain of bacteria that can survive in the high-alkaline environment of concrete. The bacteria are dormant until water seeps into a crack, whereupon they begin to feed and excrete calcite, a kind of natural cement.

U of I researchers working at the Beckman Institute for Advanced Science and Technology have previously developed self-repairing plastics using microcapsules containing a Kosher (yes, really) food additive. When small cracks begin to form in the plastic, the capsules erupt and fill them in with the nontoxic “glue.”

The team applied the same concept to metals to come up with the self-healing circuit system.

In combination, self-healing plastics and circuits could significantly lengthen the lifespan of many consumer electronic products, particularly portable electronics and gaming devices that tend to suffer stress-related damage.

That could help make a dent in the growing volume of e-waste. The average American household already boasts about two dozen electronic products, and the U.S. generates about 2.5 million tons of e-waste every year. It’s the largest growing waste stream in the country and the potential for global is is crease is astronomical.

Recycling has an essential place in e-waste management strategy, but it leads to additional environmental issues including increased global warming emissions related to shipping and mechanized dismantling operations, as well as public health and environmental hazards related to primitive recycling operations overseas.